Acetic acid, the principal constituent in vinegar, is one of the oldest fermentation products manufactured industrially. Almost all non-food industrial acetate is produced from petroleum sources. We began an integrated, multi-disciplinary systems approach in 1989 at the University of Illinois at Urbana-Champaign (UIUC) involving industrial microbiology, genetic improvement and biochemical engineering, to develop a biomass-based process for the manufacture of acetic acid and its derivatives by fermentation. Our research program focused on corn as the preferred biomass source. This is because there already exists a relatively sophisticated corn refining industry located near major markets for acetic acid and acetate derivatives such as calcium-magnesium acetate (CMA), a road de-icer. A few corn refiners have the technical knowledge, experience and financial resources to adopt acetate manufacturing technology. Many already have experience with fermentation and downstream processing, which are critical to the success of the biomass-to-acetate process.

On the other hand, "wastes" such as cheese whey, food industry by-products, pulp and paper effluents, municipal sewage, etc., have to be collected, separated, purified and concentrated before they can be used, and then converted into readily fermentable sugars. In addition, a waste-based process may not have a corn refiner's flexibility of producing a multitude of co-products that help to balance out market fluctuations of an individual product. Thus, for now at least, the quickest way to commercialize a fermentation-based acetate process is to use a ready and inexpensive source of sugar as the substrate. In the US at least, glucose (dextrose) from corn meets the criteria.

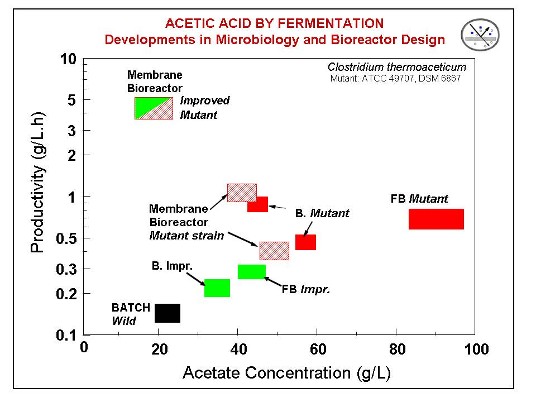

Phase I of our project involved selecting and improving appropriate strains of microorganisms to raise the level of acetate in the fermentation broth to a more economical level. Through adaptation, selection and mutation, a robust strain of Clostridium thermoaceticum (Moorella thermoacetica) was developed with good tolerance to acetate and sturdy enough to withstand repeated handling and continuous operation in high-rate bioreactors. This strain has been deposited with ATCC and with DSM, so that industry and other researchers can expedite commercialization.

With a view to rapidly commercializing this process, the following goals were set for Phase II of the R&D program, which began in 1992:

- Design high-performance bioreactors to improve fermentation productivity,

- Design and optimize downstream processing operations for recovery of acetate from the broth,

- Reduction of material costs (e.g., using cheaper nutrients),

- Scale-up to pilot scale, process design and cost estimates.

All targets for Phase II were successfully achieved. As shown in the diagram above, the productivity of the fermentation and the product concentration were increased by a combination of microbiology (mutation/selection), and biochemical engineering (bioreactor design). From a 2% acetate concentration with the wild strain in a batch fermenter (designated "BATCH Wild" in the figure), we improved the strain in batch fermentation (designated "B.Impr.") and achieved 10% acetate concentration with a mutant strain in a fed-batch ("FB") fermenter. Very high productivities were obtained with continuous membrane recycle bioreactors ("Membrane Bioreactor"). As expected, there is an inverse relationship between productivity and product concentration in such high-rate bioreactors. The membrane bioreactor has been operated for up to 54 days continuously with good stability and steady outputs. Several acetate salts (sodium, potassium, ammonium, calcium-magnesium/CMA) have been produced.

Alternate low-cost nutrients for this fermentation were then screened and the organism adapted appropriately. Since these alternate nutrients are corn-based and/or soy-based, it will further enhance the value of the co-products from these industries while lowering the cost of production of acetate.

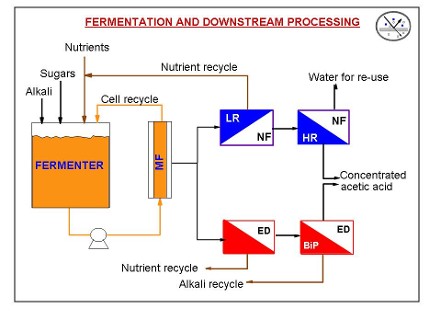

Downstream processing has focused on membrane technology for the purification and concentration steps. As shown in the diagram below, the primary cell separation and recycle step is done with microfiltration (MF) membranes. The cell free broth is then processed by nanofiltration (NF) using a combination of low-rejection (LR) and high-rejection (HR) membranes to isolate and preconcentrate the acetate. Electrodialysis (ED) is another membrane technology that can produce a 30% product stream. This should obviate the need for about half the evaporation capacity. Most important, both these membrane technologies allow for recycle of the nutrients and the alkali if bioplar ED is used ("BiP" in the figure)..

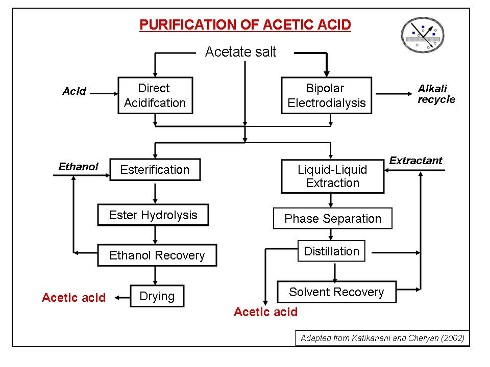

Phase III of the research program began in 1996 and was completed in 1998. We developed methods for conversion of acetate salts in the fermentation broth into the acid form and its subsequent purification to industrial grade acetic acid. This was accomplished with techniques such as bipolar electrodialysis, liquid-liquid extraction, vacuum distillation and esterification. The manufacture of higher-value products such as ethyl and butyl acetates was also investigated.

CMA and other acetates

Acetic acid has numerous uses as an industrial chemical which need no further elaboration. Calcium-magnesium acetate (CMA) was our first commercial target. It is being promoted as a road salt substitute. This "nicer de-icer" (a name given to it by an 8th grade student for a science fair project) is as an environmentally safe alternative to chloride salts for de-icing roads. The cost of CMA may seem high compared to chloride road salts. However, we pay a much higher net price when the effects of chloride salts are considered, e.g., damage to highways, bridges, concrete structures, vehicles, roadside vegetation, ground water contamination and other environmental effects. Estimates of the damage caused by chloride salts range from $1000 to 2000/ton of salt. In this light, the price of CMA is reasonable.

CMA can be produced by reacting acetic acid with dolime (high-magnesium lime). The cost of CMA could be comparable to petroleum-derived acetate if it could be produced (via fermentation) from cheaper raw materials (e.g., biomass). We focused on the direct anaerobic fermentation route rather than the indirect aerobic (vinegar) process due to its higher yields and potentially lower costs. Independent laboratories have confirmed that the calcium:magnesium ratio of our corn-based CMA (called U-OFF-ICE) is similar to the petroleum derived product. Other tests show that U-OFF-ICE has good ice-melting properties.

Other points to note:

- CMA has been approved as an airport runway de-icer by the FAA.

- CMA can be used in coal-fired boilers to combat sulfur-dioxide emissions when high-sulfur coal is burnt. This in turn mitigates the problem of acid rain.

- There is some evidence that the fermentation-derived acetate could also be useful in reducing nitrous oxide emissions.

- Acetates are now being used for the manufacture of environmentally safe heat transfer fluids in heat pumps.

- Food additives such as vinegar and sodium acetate, used as acidulants and for preservation of fresh meat.

Publications on this topic

Publications on this topic