The Dairy Industry

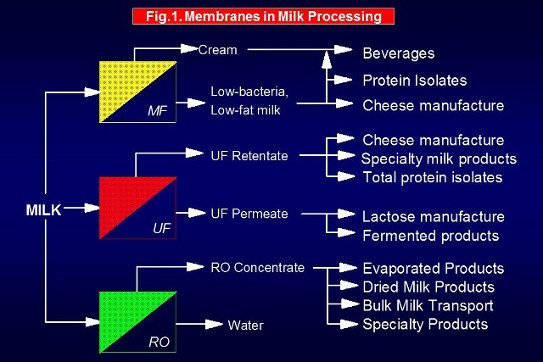

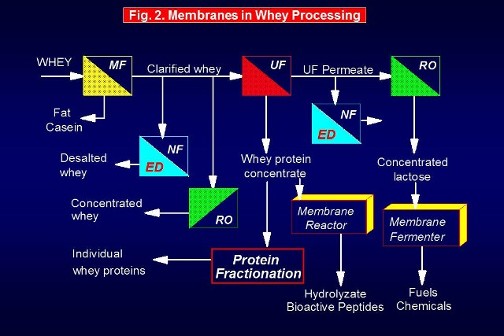

The potential application of membranes in the dairy industry is vast, as shown in Figure 1 for milk and in Figure 2 for cheese whey. To successfully process a complex material such as milk and its by-products with membranes requires an understanding of the interactions between individual components of milk under different processing conditions. Diverse factors impose additional limitations, the most important being that, as a food product, the membrane process must follow certain sanitary guidelines, which imposes further limitations on the selection of the membrane and other materials of contact.

As shown in Figure 1, membrane applications in milk processing include :

- The production of milk protein concentrates and isolates (containing up to 90% protein on a dry basis) by ultrafiltration,

- Microfiltration of dairy liquids to reduce microbial loads ("cold sterilization"), for selective fractionation of dairy components and for enhancing functional properties of dairy ingredients,

- Production of cheese using ultrafiltered milk; both soft (e.g., cottage) cheese and hard (e.g., cheddar) cheese production from UF-milk retentate have been studied,

- Concentration of milk by reverse osmosis, to save energy in the manufacture of concentrated and dried milk products, and to reduce bulk transportation and refrigeration costs.

A good example of the successful application of membrane technology, and ultrafiltration in particular, is the processing of cheese whey. Whey is a by-product of the cheese industry. It is the liquid fraction that is drained from the curd during the manufacture of cheese. Typically every 100 kg of milk will give about 10-20 kg of cheese depending on the variety, and about 80-90 kg of liquid whey. Its disposal is a major problem for the dairy industry, partly due to its composition. It has a low solids content and a very unfavorable lactose:protein ratio which makes it difficult to utilize as-is. The biological oxygen demand (BOD) is 32,000 to 60,000 ppm, which creates a very severe disposal problem.

Efforts continue worldwide to find uses for the whey, either as-is or in dry form, or its major components (high quality protein and lactose) Since cheese consumption is increasing around the world, we can assume that the whey utilization problem is getting worse. This explains why membrane technology has attracted the attention of cheese and whey producers: the appropriate membrane can simultaneously fractionate, purify and concentrate whey components, thus enhancing their utilization and reducing the pollution problem. Figure 2 shows a general schematic of possible applications of membranes in whey treatment.

Some of the applications of membranes in cheese whey processing include:

- Reverse osmosis of whey prior to evaporation and drying,

- Ultrafiltration of whey to produce whey protein concentrates (WPC) of varying protein contents from 35% to 80% protein,

- Converting the lactose to higher-value products by fermentation (e.g., ethanol, lactic acid) or by enzyme hydrolysis in continuous membrane reactors,

- Microfiltration of whey as a pre-treatment for ultrafiltration, to allow the production of purified whey protein isolates (with more than 90% protein on a dry basis)

We have considerable experience in membrane processing of milk and whey for producing MPC, WPC, WPI, micellar casein, enriched protein fractions, lactose conversion to fuels and chemicals and more. Contact us if you want to incorporate these technologies in your plant.

_____________________________________________________________

References:

Cheryan, M. 1998. Ultrafiltration and Microfiltration Handbook. CRC Press/Taylor & Francis, Boca Raton FL.

Publications on this topic

Publications on this topic